Controlled atmosphere

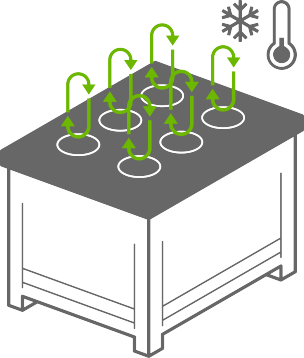

How does it work?

-

The 1st of the modern technologies of storage that is used right up to the consumer's home is of course the cold. This cold will provoke a first decrease in respiration, thus providing a first potential extension of storage.

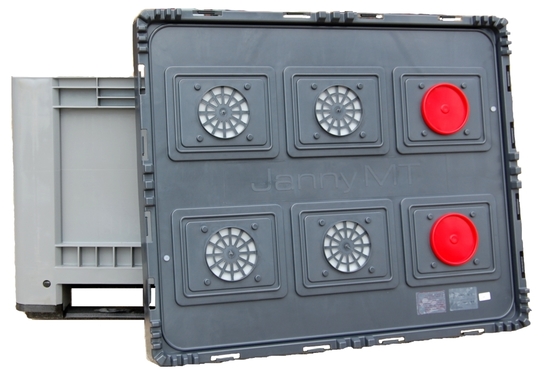

When the Janny MT lid is clipped onto a bin filled with products whose breathing intensity is reduced by the cold, its tightness seal maintains the humidity of the stored products. Its selective permeability membranes stabilize oxygen and CO2 levels between 1 and 5%, using the O2 absorption of the products' breathing as the engine. This decrease in oxygen causes a second decrease in respiration, thus further increasing the possible duration of storage.

The simultaneous adjustment of the 3 pillars of storage (temperature, relative humidity & O2 / CO2 balance) obtained in the modules placed in cold room thus provides the best storage quality in a natural way: this is the Janny MT sustainable quality.

The same equipment (the modules) works on more than 20 vegetables, 15 fruits, 3 mushrooms and 3 species of flowers. It is just needed to close more or less membranes, thanks to the removable caps, to adapt the equipment to the stored product.

-

Harvest

of your fruits, vegetables, flowers, mushrooms... -

Cooling

open module in cold room -

Storage

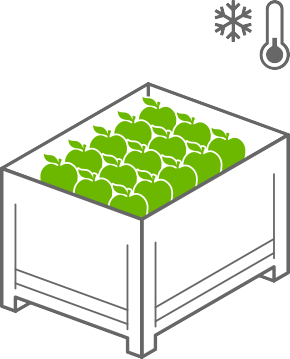

closed module in cold room -

Readaptation

open module in cold room -

Sales

of your fruits, vegetables, flowers, mushrooms ...

The benefits of CA bins

-

Weight loss reduction

In a cold room the products are generally stored in opened crates or bins. The cooling is ensured by a cooling unit that circulates air in the room. When the air is cooled by the cooling unit, it dries out before being ventilated. In contact with the products to be cooled, the air heats up and then acquires a capacity to absorb humidity: it thus captures a little water each time it passes over the product, and thus gradually makes it lose its freshness and possible crunchiness. For example, on apples or cherries, weight losses of around 10% are common at the end of storage in conventional packaging; for a product such as chestnuts, this can be as much as 20%!

With the Janny MT process, these are the modules that are cooled. It is then the walls of the modules that cool the products without drying them out; the weight loss is then reduced to a maximum of 1.5%. For products sold by weight, the economic gain is obvious. -

Increase in marketed volumes

The Janny MT process gives growers and marketers the ability to shift sales, depending on the product, by several days, weeks or months from harvest. This ability allows them to harvest or purchase products even if the market is not able to absorb them immediately. Cherries left on the trees, or leeks left in the field that end up crushed after bolting, are examples of non-harvest losses that become avoidable: the products can be quietly picked at optimal maturity, to be then sold according to market needs. Some losses due to bad weather can also be avoided.

Losses in the field or during storage are therefore reduced, which converts into increased volumes sold at the right time for the market. -

Maintain quality during storage

Having the possibility to keep freshness and quality longer gives more time to market the products in first quality. As a result, many users of CA modules have greatly reduced their need for processing. There is no longer any need to send apples to the industry: they can be marketed fresh for several more months.

Given the price differences between 1st category and industry, the economic benefit is major. -

Choice of sales channel

Another mechanical consequence of increased post-harvest flexibility is that there is no longer a need to sell at low prices due to downgrading when conventional cold no longer maintains quality.

Products can be offered for longer periods of time, much to the delight of consumers. This is thus possible with more remunerative prices for growers and distributors. ! -

Choosing the best time to sell

Agricultural raw materials are, like other commodities, subject to the law of supply and demand. When a production peak occurs, the market can quickly become saturated with commodities, causing prices to fall.

Having the capacity to preserve products for longer periods of time while keeping their freshness allows the marketing of part of the volumes harvested during the peak season to be shifted to the off-season, often at more advantageous prices. For example, our peony growers customers, whose production peaks in spring, have a major economic interest in shifting their sales to the wedding high season in summer. Similarly, blueberry growers have an interest in selling their August production at the end of September. -

A destocking flexibility unmatched in CA

Only take out of storage the quantities necessary for the market needs, and keep the rest of the volumes in optimal storage conditions.

CA modules are the only solution that combines such flexibility in storage with the shelf life allowed by optimal O2 and CO2 levels. -

And more...

The interests cited above are all drawn from the experience of our clients. But if we wanted to be exhaustive, we would also have to detail how the use of CA modules, possible with several products successively during the same season, allows some to save on labor, to free themselves on weekends, to accelerate the rotation of their crop plots, to simplify their technical itineraries, to build customer loyalty... but we prefer even more to explore all this with you by accompanying you in the setting up of your storage project!

-

The Fruit range

-

blackcurrant up to 40 days

blackcurrant up to 40 days -

cherry up to 25 days

cherry up to 25 days -

chestnut up to 2.5 months

chestnut up to 2.5 months -

fig up to 1 month

fig up to 1 month -

strawberry up to 12 days

strawberry up to 12 days -

raspberry up to 11 days

raspberry up to 11 days -

passion fruit up to 80 days

passion fruit up to 80 days -

pomegranate up to 6 months

pomegranate up to 6 months -

redcurrant up to 40 days

redcurrant up to 40 days -

kiwi up to 5 months

kiwi up to 5 months -

blueberry up to 6 weeks

blueberry up to 6 weeks -

pear up to 7 months

pear up to 7 months -

apple up to 10 months

apple up to 10 months -

plum up to 50 days

plum up to 50 days -

table grape up to 5 months

table grape up to 5 months

-

-

The Vegetable range

-

asparagus up to 25 days

asparagus up to 25 days -

red beetroot up to 5 months

red beetroot up to 5 months -

broccoli up to 1.5 month

broccoli up to 1.5 month -

cardoon up to 1.5 month

cardoon up to 1.5 month -

white / red cabbage up to 6 months

white / red cabbage up to 6 months -

chinese leave up to 4 months

chinese leave up to 4 months -

Brussel sprout up to 2 months

Brussel sprout up to 2 months -

cauliflower up to 1.5 month

cauliflower up to 1.5 month -

curly kale – Milan up to 6 months

curly kale – Milan up to 6 months -

Swiss chard up to 28 days

Swiss chard up to 28 days -

spinach up to 15 days

spinach up to 15 days -

fennel up to 30 days

fennel up to 30 days -

bean up to 20 days

bean up to 20 days -

lamb's lettuce up to 21 days

lamb's lettuce up to 21 days -

turnip up to 4 months

turnip up to 4 months -

new potato up to 90 days

new potato up to 90 days -

pak choi up to 60 days

pak choi up to 60 days -

leek up to 3 months

leek up to 3 months -

sugarloaf up to 2 months

sugarloaf up to 2 months -

radicchio up to 4 months

radicchio up to 4 months -

bunch radishes up to 1 month

bunch radishes up to 1 month -

radishes with stems removed up to 2 months

radishes with stems removed up to 2 months -

black radish up to 3 months

black radish up to 3 months -

lettuce up to 21 days

lettuce up to 21 days -

jerusalem artichoke up to 90 days

jerusalem artichoke up to 90 days

-

-

The Mushroom range

-

The Flower range

-

The Aromatic range

-

The condiment range